Dishwashers and washing machines used for Industrial type

Drinking water and water filling facilities

Heating and cooling systems

Closed circuit cooling systems (Chiller)

In dyehouses and dyed liquid pumping

Food industry (soft drinks, juice and milk factories)

Heating and air conditioning systems

In pumping glycol solutions

Low corrosive industrial and chemical liquids

Biodiesel in plants

Flue gas treatment systems

Fruit and vegetable washing machines

Steel pots manufacturing and polishing

Nuts salting process

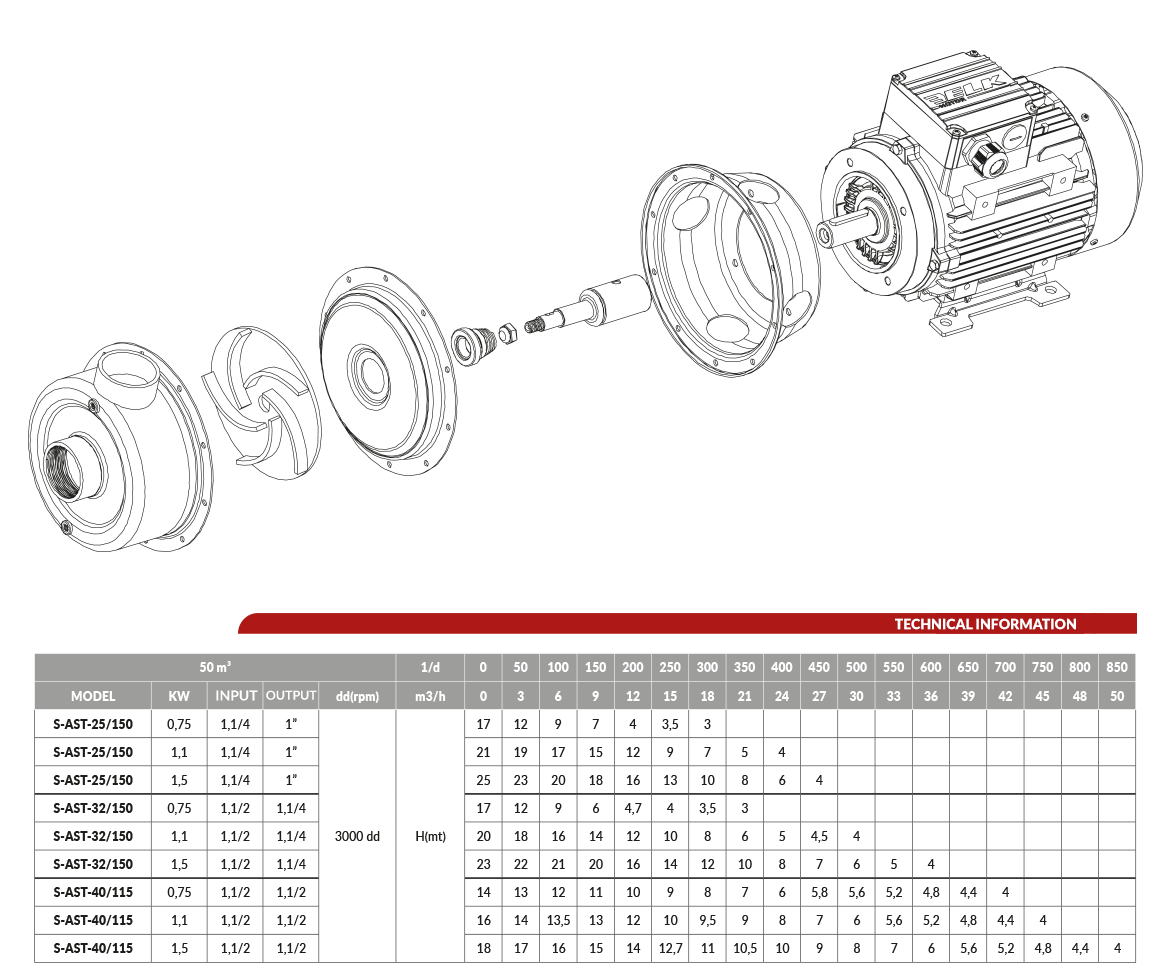

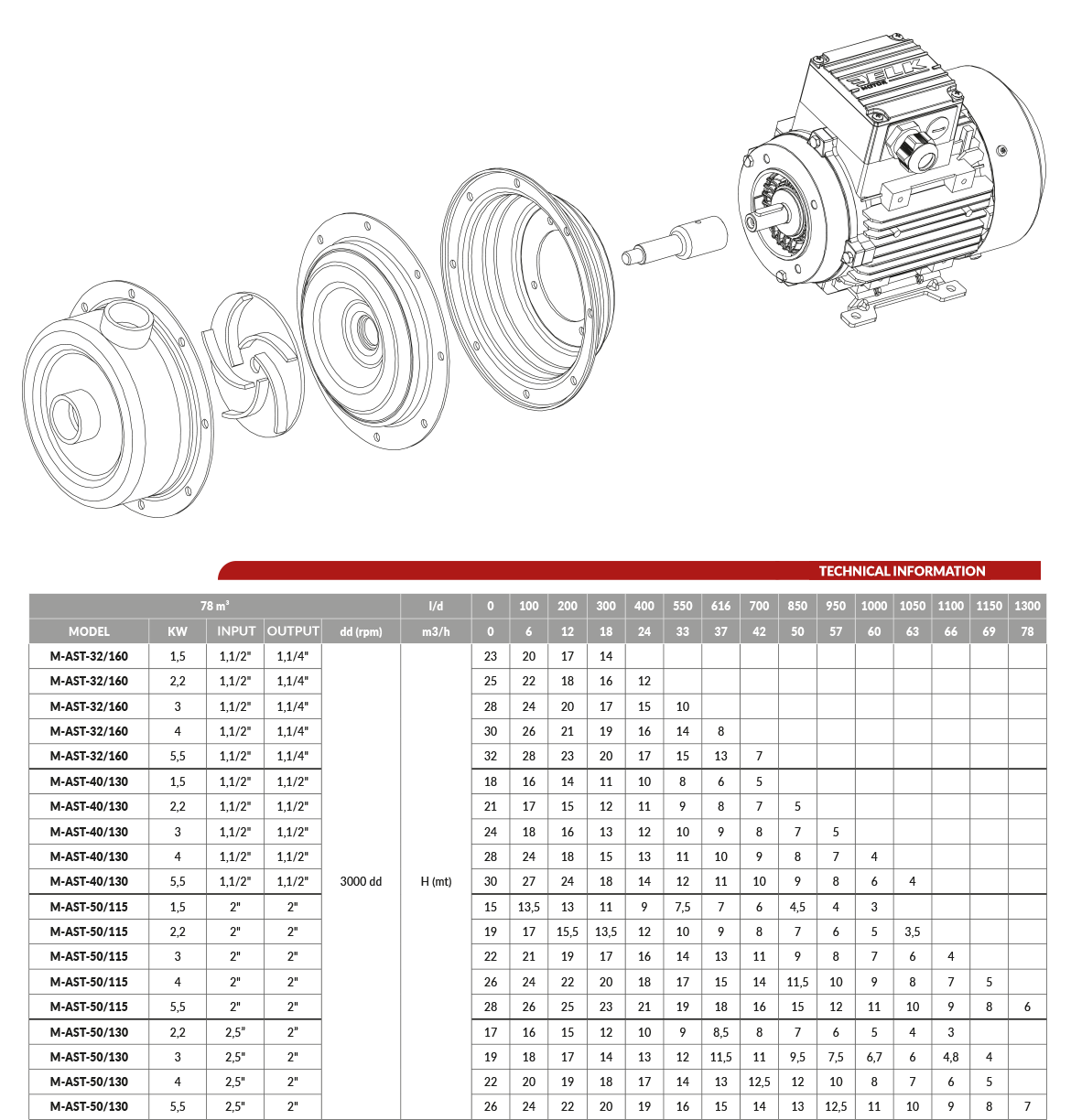

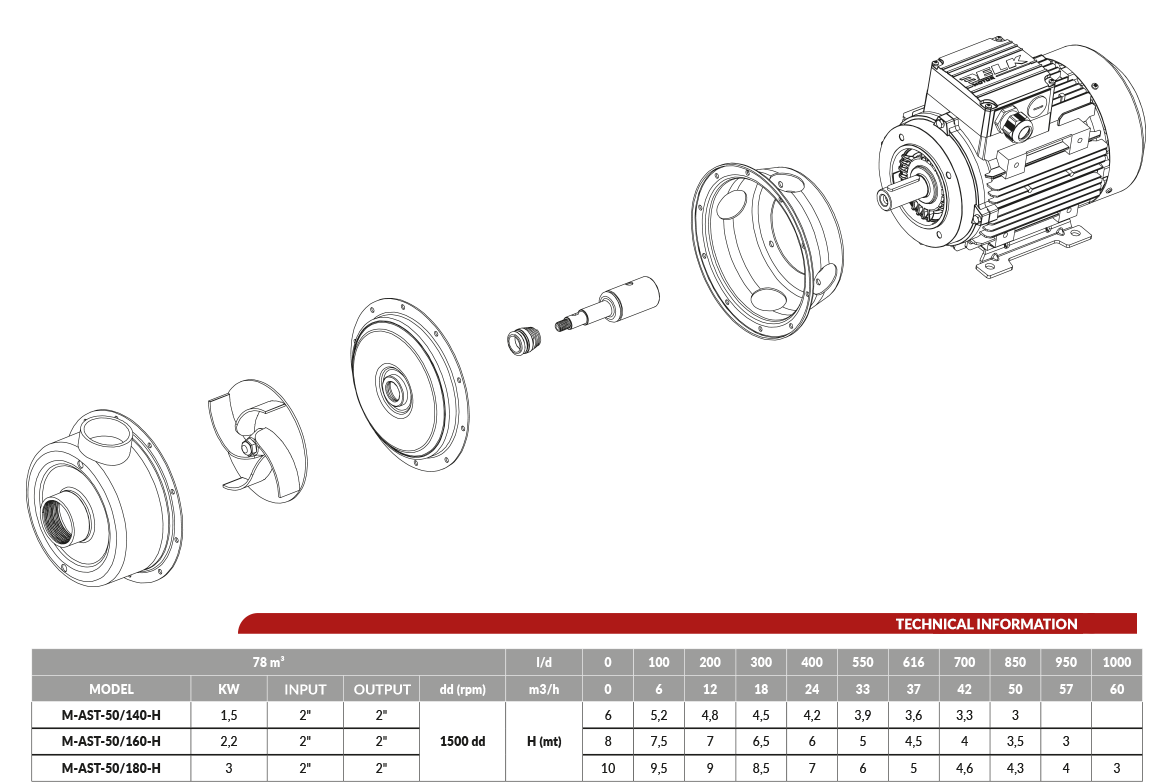

Pump Structure

Pump part (impeller shaft, back cover) is made of 304, 316, 316L stainless steel.

All models according to different requirements we produce have a special interconnect coupling which prevents the engine from burning in case of any leakage of liquid. In this way, increasing of the failure cost prevented.

According to requirement, different type of seal is selected.

The liquid pumping temperature is between -15 ° C and +110 ° C.

If a special mechanical seal is used, the maximum fluid discharge temperature of the pump can be increased up to 120 ° C.